-

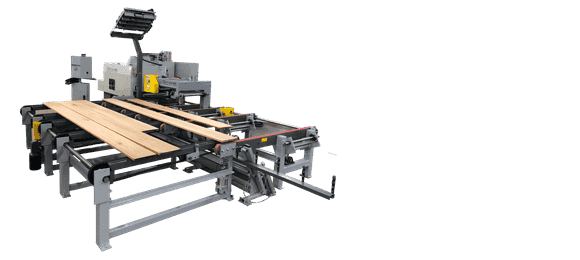

High tech machinery for automating and improving common rough mill processes

High tech machinery for automating and improving common rough mill processes

-

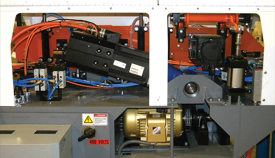

Saws

Explore category -

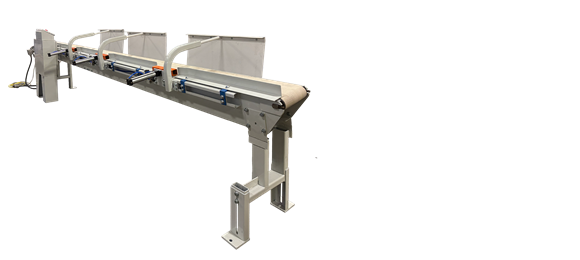

Sorters

Explore product -

Scanners

Explore category -

Cameron

Explore brand